If you have an edit to your order or want to cancel your order in our system, please call and talk to our customer service, 1-800-531-2666. There has been an influx of Contact Form Emails and some of these requests are not caught until after our shipping department has finished processing/shipping the order out.

NOTICE: We are experiencing delayed delivery times with orders shipped with USPS. Be aware it will take longer than normal (even up to 3+ weeks) to receive any Packages chosen to go USPS - Parcel Post & Priority Mail. As of Feb 28, 2024, if you choose Graf's Choice of Carriers, we are directing packages to ship other than USPS to get the order to you in a timely manner.

Orders with Hazmat may be delayed 3-5 business days.

Reminder: Credit cards are charged when your package is ready to ship. Also check out our FAQ page.

TIPTON BEST GUN VISE 360 FOR ALL FIREARMS + BOWS

TIPTON BEST GUN VISE 360 FOR ALL FIREARMS + BOWS

MTM IN-SAFE HANDGUN CLEAR STORAGE CASE 12" 3-pk 4cs

MTM IN-SAFE HANDGUN CLEAR STORAGE CASE 12" 3-pk 4cs

RIO 20ga TOP TGT 7/8oz 1250fps #7.5 250/cs

RIO 20ga TOP TGT 7/8oz 1250fps #7.5 250/cs

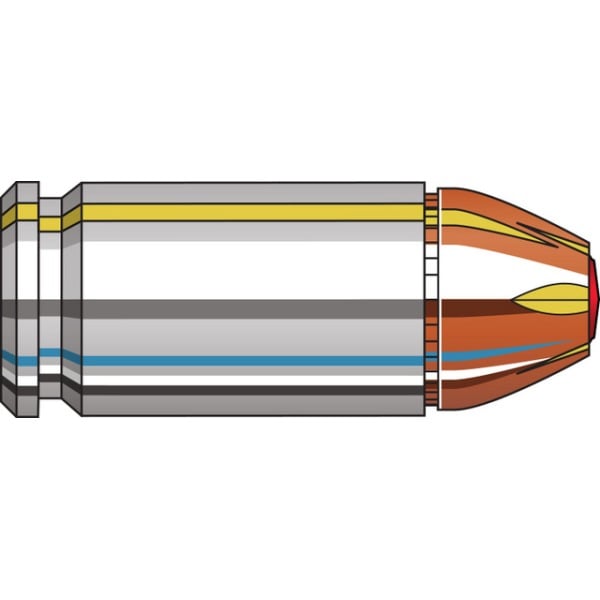

HORNADY AMMO 380 ACP 90gr FTX CRITICAL-DEF. 25/BX 10/CS

HORNADY AMMO 380 ACP 90gr FTX CRITICAL-DEF. 25/BX 10/CS

Forster Co-Ax B-5 Single Stage Reloading Press with S-Jaws

Forster Co-Ax B-5 Single Stage Reloading Press with S-Jaws

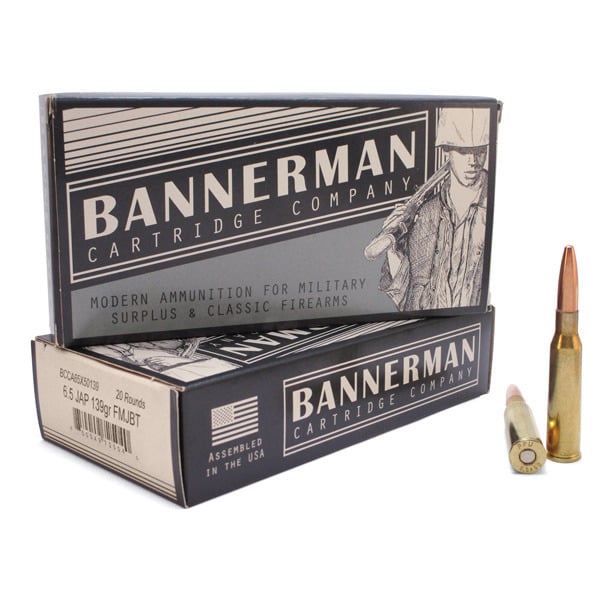

BANNERMAN AMMO 6.5x50 JAP 139gr FMJBT 2235fps 20/bx

BANNERMAN AMMO 6.5x50 JAP 139gr FMJBT 2235fps 20/bx

WF TRAP/SKEET ORANGE TOP STANDARD 135/CS 63/PLT

WF TRAP/SKEET ORANGE TOP STANDARD 135/CS 63/PLT

ON TARGET AMMO 44 MAG 240g XTP JHP 50/bx 14/cs

ON TARGET AMMO 44 MAG 240g XTP JHP 50/bx 14/cs

USED BRASS 9MM LUGER SEMI-PROCESSED PER 1000

USED BRASS 9MM LUGER SEMI-PROCESSED PER 1000

SCHUETZEN BLACK POWDER 2F 1LB 25/CS

SCHUETZEN BLACK POWDER 2F 1LB 25/CS

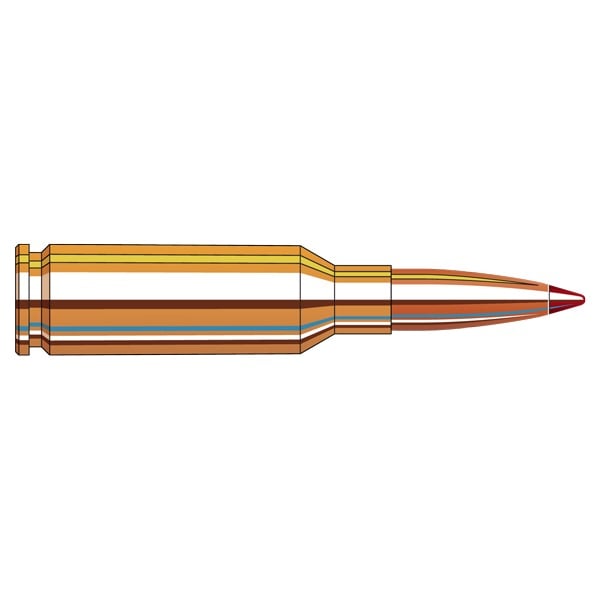

HORNADY AMMO 6MM ARC 108gr ELD MATCH 20/BX 10/CS

HORNADY AMMO 6MM ARC 108gr ELD MATCH 20/BX 10/CS

LEE 9MM LUGER CARBIDE DLX 4 DIE SET, S/H #19

LEE 9MM LUGER CARBIDE DLX 4 DIE SET, S/H #19

Starline Brass 6mm ARC Unprimed Bag of 100

Starline Brass 6mm ARC Unprimed Bag of 100

Peterson Brass 284 Winchester Unprimed Box of 50

Peterson Brass 284 Winchester Unprimed Box of 50

ALPHA BRASS 6MM DASHER UNPRIMED SRP 100/bx

ALPHA BRASS 6MM DASHER UNPRIMED SRP 100/bx

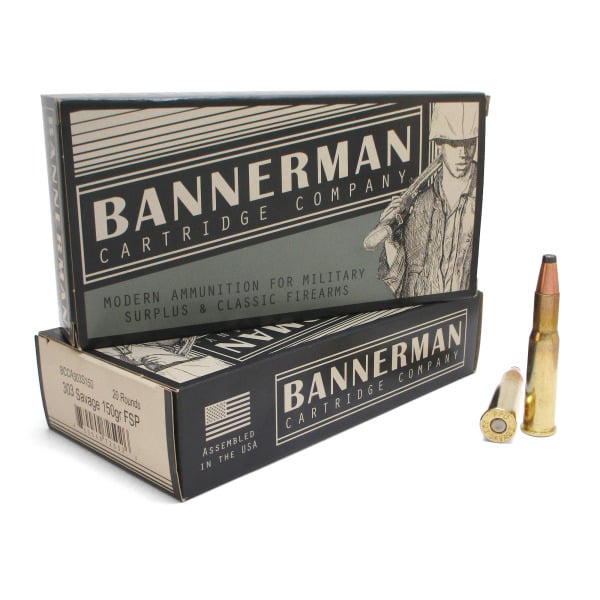

BANNERMAN AMMO 303 SAVAGE 150gr FSP 20/bx

BANNERMAN AMMO 303 SAVAGE 150gr FSP 20/bx

GARMIN XERO C1 PRO CHRONOGRAPH w/BLUETOOTH

GARMIN XERO C1 PRO CHRONOGRAPH w/BLUETOOTH

HORNADY PRODUCT CATALOG 2024

HORNADY PRODUCT CATALOG 2024